A Complete Guide to Surgical Instrument Quality Control

Behind the Factory: Quality Control Inspections of Each Surgical Instrument

Surgical tools in the context of contemporary healthcare can be described as more than mere tools themselves since they are highly engineered products that influence patient safety, surgical outcome, and physician confidence directly. One failure can destroy the whole process. This is why quality control in the manufacture of surgical instruments is not a choice; it is a process that is staged and demanding in terms of achieving the highest standards in the world.

This under-the-hood view provides an insight into the quality checklist that each surgical instrument undergoes, whether it is at the raw material level, package, or even the finished product, to ensure reliability, durability, as well as compliance before this instrument finally finds its way into an operating room.

The Foundation of Quality Verification of a Raw Material

Quality is monitored way before an instrument is formed. It starts with examination of raw material that is normally medical grade stainless steel, titanium alloys or specialty metals.

Every consignment of material is inspected:

- Making it corrosion-resistant by chemical composition

- Durability with stress mechanical strength

- Documentation of traceability of regulatory compliance

The production of materials is only approved of those of high quality that address the international standards like ISO and ASTM. The substandard materials are scrapped in order to avoid breakdown in the downstream.

Accuracy Checks of Precision and Dimensional Checks

After approval of materials, they find their way into forging, CNC machining or laser cutting, depending on the type of instrument. At this level, dimensional accuracy is of paramount importance.

Quality teams perform:

- On-process inspection Digital gauges and calipers

- Checking of tolerance to have precise measurements

- Checking of articulated instruments alignment and symmetry

A small deviation of a few millimeters can affect surgical performance, especially when using the orthopaedic, maxillofacial and minimally invasive instruments.

Heat treatment and Hardness test

Heat treatment is used to increase wear resistance, flexibility and strength. However, overheating can be processed wrongly and this will either lead to brittleness or premature failure.

In order to avoid it, manufacturers produce:

- Hardness test done by Vickers or Rockwell

- Stress-relief verification

- Microstructure analysis

These tests are important in ensuring that the instrument attains the optimal ratio between doneness and flexibility so that it will withstand repeated sterilization processes and surgical applications.

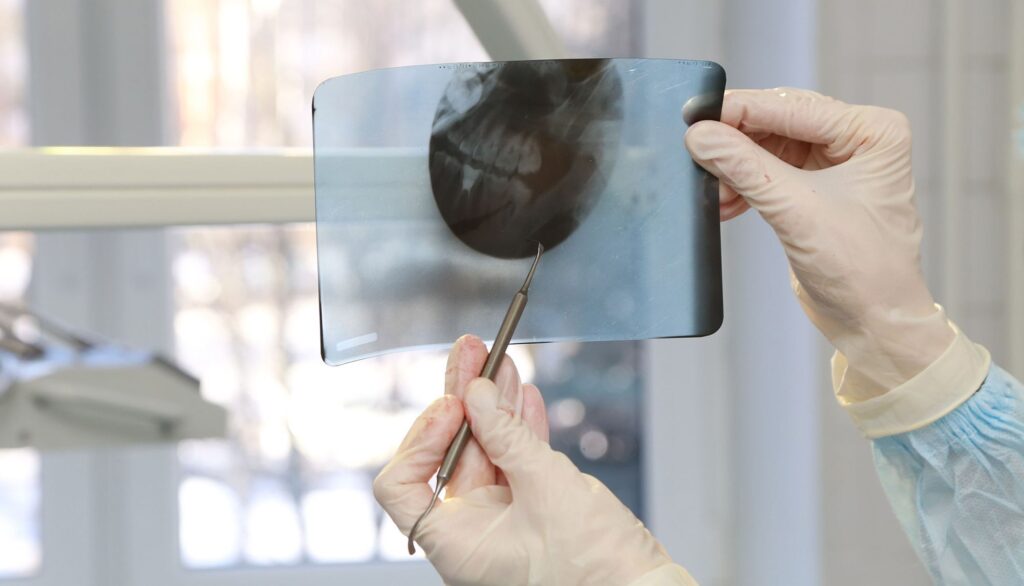

Surfaces and Finishing: Visual Inspection

The quality of surfaces is not about beauty only, but it has immediate implications on the hygiene, corrosion and cleaning ease.

- Then instruments are polished, satin finished or passivated

- Increased eye observations to detect scratches or pits

- Smoothness of surface tests to avoid bacterial retention

- Inspection of cutting instruments using edge consistency

Any flaw that has the potential to affect the performance or sterility results in rework or rejection.

Real-World Performance Testing: Functional Testing

Functional testing also makes sure that the instrument will work as intended in operation.

There may be tests depending on the type of instrument:

- Posture of the jaw and gripping force test

- Testing of hinges and joints’ movement from a distance

- Reducing scissors, osteotomes, and chisels testing processes

These tests are like real practices in surgery meaning that they are reliable in such pressurizing situations as operating rooms.

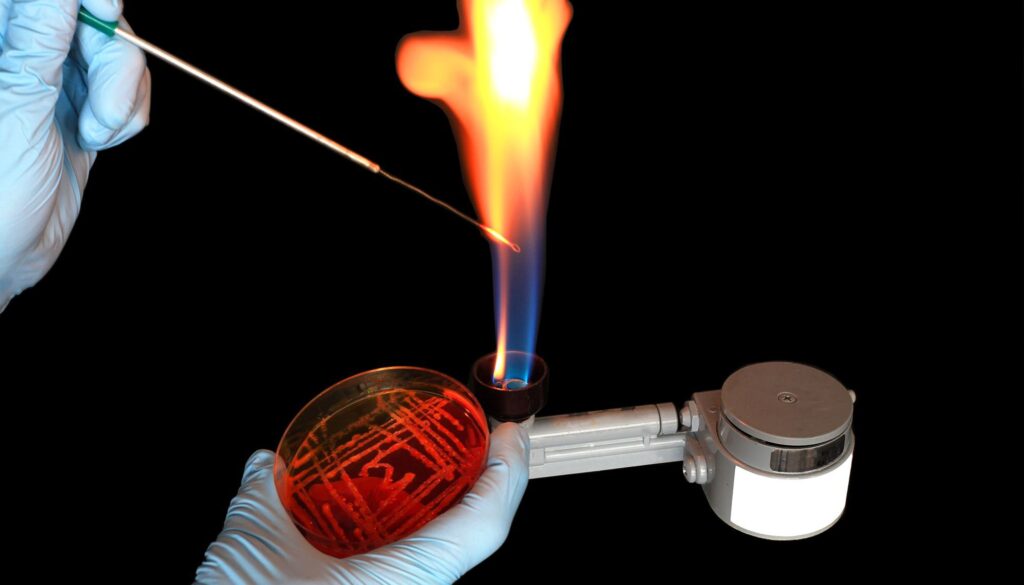

Passivation testing and Corrosion Resistance testing

The surgical instruments should be subjected to moisture, chemicals, and high-temperature sterilization separately. Manufacturers undergo corrosion resistance testing in order to make them last longer.

This includes:

- Passivation to eliminate the liberated iron test

- Tests of salt spray or chemical exposure S

- Autoclave process simulation

Those instruments, which pass these tests, are only proceeded with when they exhibit integrity and are completed.

Cleaning, Contamination Control and Ultrasonic Washing

Instruments are well cleaned before final inspection to eliminate oils, debris and minute particles.

At this stage, quality checks are done to make sure:

- No residual contaminants

- Meeting the cleanliness standards

- Before being put in packaging, safe handling is done

Ultrasonic cleaning and a controlled environment contribute to the maintenance of the hygiene of the medical grade.

Last Quality Inspection and Records

The last check is a thorough check of the instrument in all aspects.

This includes:

- Re-checks at the visual level and functional level

- Checking and marking of verification

- Serial and batches of traceability

Quality assurance teams record all operations, which is in line with the international regulation provisions and audit preparation

Packaging Sterility and Assurance of Integrity

The last safeguard between the factory and the operating room is packaging.

Quality control ensures:

- Right sealing and packaging ability

- Extravagant inductions and prescriptions

- Insurance against shipment damage

The packaging is tested to be sterile and non- sterile to receive instruments in an ideal condition.

The rationale of Why These Quality Control Checks Are Important.

All quality checks are aimed at one goal, which is patient safety and surgical excellence. Surgeons trust the instruments they use that work perfectly, hospitals expect to see uniform quality, and manufacturers must face the challenge of ensuring the global standards in healthcare.

Rigorous quality control:

- Reduces surgical risks

- Extends the time of playing the instrument

- Establishes a relationship with medical personnel

- Assures regulatory systems across the globe

Summary

The quality control process of the surgical instruments is detailed and uncompromising behind all the tools. At the point of selecting the raw material all the way to the end of packaging, every process is made to be precise, safe, and reliable.

When you lay your hands upon one of the instruments of surgery, you are not handling a product, but some measure of skill, experimentation and quality assurance that you are handling.